Areas we cover - London, Surrey, Sussex and Kent

(other areas are covered for our clients

that we provide services for, by request)

Areas we cover - London, Surrey, Sussex and Kent

(other areas are covered for our clients

that we provide services for, by request)

What is planned preventative maintenance? Planned preventative maintenance (PPM) allows you to substantially reduce reactive maintenance and retain your buildings and assets in the desired or needed quality.

Planned preventative maintenance (PPM) is a proactive maintenance strategy that prevents unexpected equipment and machinery failures through regular scheduled inspections, services, and repairs. Which is why it is also referred to as scheduled maintenance.

The concept of PPM is to ensure equipment is in working order for as long as possible by regularly planning maintenance and checks, instead of waiting for equipment to fail. The goal is to catch an issue or potential hazard before it’s too late.

A PPM schedule aims to combat issues such as ageing equipment, unplanned downtime, and unexpected maintenance costs.

Reactive maintenance is the opposite of preventative maintenance and mainly involves responding to issues as and when they emerge, including random breakdowns or equipment failures. Even with sufficient preventative maintenance, accidents and faults might still happen and require a rapid response.

Depending on the company and its financial situation, it may be more cost-effective to employ reactive maintenance rather than checking the equipment at regular intervals – though it’s usually most efficient to use both types of maintenance.

At GGS Maintenance Ltd. we provide our clients with an emergency call out service, 24hrs a day, 365 days of the year.

Services We Provide

Planned Preventative And Reactive Maintenance

–Safety Checks: Conducting regular safety checks to identify and address potential hazards.

–Property Condition Surveys: Assessing the overall condition of a property and identifying areas that require attention.

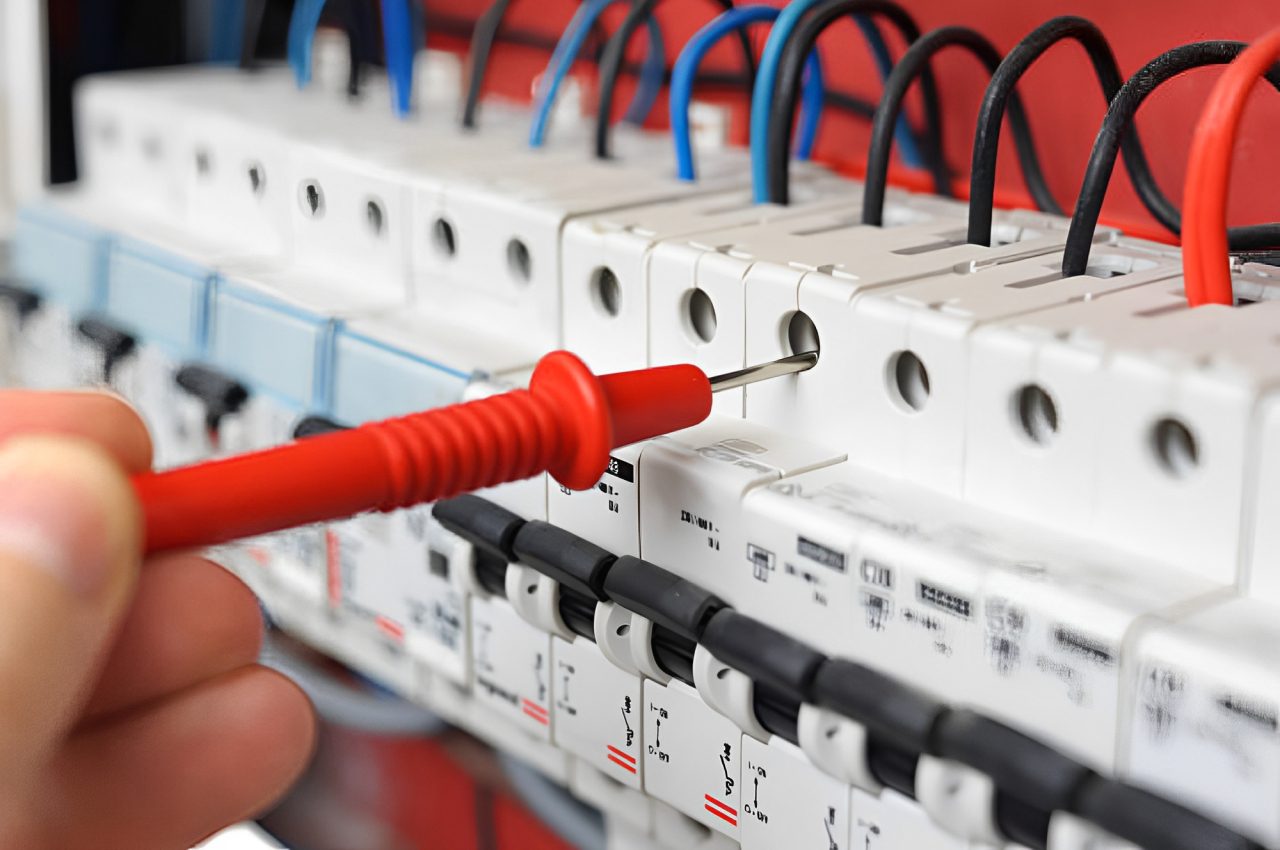

–Electrical: Ensuring compliance with electrical safety standards, testing emergency lighting and inspecting electrical wiring (EICR).

–Plumbing: Maintaining and servicing plumbing systems, including hot water systems (water temperature checks and legionella sampling), and addressing any leaks or issues.

– Boilers: Regular servicing of boilers and gas safety checks.

–HVAC: Servicing and maintaining heating, ventilation, and air conditioning systems.

–Roofing: Inspecting roofs for damage, leaks, and wear and tear..

–Compliance: Ensuring adherence to relevant regulations and standards

More services available upon request.